Careful steps at harvest time can both maximise the tonnage of forage maize harvested and optimise the quality of maize silage at feed out.

Assess Dry Matter Content in the Field

The table below helps assess dry matter content. If the grain in your forage maize is at the ‘cheddar’ like stage and the stover (stem and leaf) is either ‘yellowing’ or ‘straw like’ the table below shows how this leads to an overall dry matter percentage between 30% and 33%. Use the table to quickly assess the dry matter in your field.

So far very little frost has occurred. If a killing frost affects your crop this will desiccate the plant and drive the dry matter percentage up rapidly. Once completely frosted a crop should be harvested as no further starch will be formed.

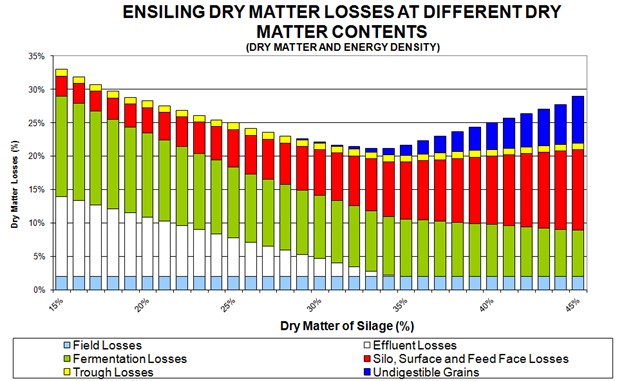

Harvest at a dry matter content between 28% and 35%

In this range dry matter losses in the harvesting and ensiling process are minimised as can be seen from the chart above.

Set Chop Length and Kernel Processer

The best compromise between fermentation requirements and cow rumen function demands is a chop length of between 10mm to 20mm theoretical length of chop (TLC), depending upon the crop. This will allow for:

- Proper silage compaction and oxygen exclusion preventing heating, moulding and aerobic instability.

- Adequate effective fibre to meet the rumen function demands of the cow, reducing the chances of digestive upsets and milk fat depression.

- Maize silage should be chopped at 5mm to 20mm. Longer chop can create difficulties in consolidation, proper functioning of clamp unloaders, more intact pieces of kernels passed in the manure, preferential sorting of stover or larger cob pieces in total mixed rations (TMR).

- Chopping shorter than 5mm (TLC) is conducive to better packing (especially with late harvested, dry crops) and can increase silo capacity. However, it requires more power and may slow harvesting.

Fill, Consolidate and Seal

The crop should be harvested and ensiled as rapidly as possible. Filling delays will result in excessive respiration and increased silage dry matter losses.

In fact the first three rules of clamp silage management are consolidate, consolidate and consolidate!

Before filling cover sides of clamps with 4 to 6mm plastic sheeting and leave enough spare to overlap with the top sheet once the top sheet is laid. Consider using a heavier reusable cover rather than plastic sheeting for the top cover. The vehicle used to consolidate the clamp must have the maximum possible weight to surface area ratio so that the pressure exerted on the silage is maximised. Look for moisture on the tractor tyres as an indicator of enough moisture for adequate packing.

Consider laying a thin plastic sheet under the main top sheet. The initial respiration in the silage causes carbon dioxide to be produced which exits the clamp lower down since it is heavier than air. This causes a siphon effect which sucks such a thin sheet to the top of the silage creating a better seal.

Consider using a silage additive

It is wrong to assume good forage cannot benefit from the use of an appropriate additive, or that silage problems cannot be avoided by using one. Microbial additives such as Pioneer Brand 11A44 and Pioneer Brand 11C33 are well proven to reduce the growth of spoilage organisms especially in silages that are difficult to consolidate and where air exclusion cannot be fully achieved. An additional benefit when using 11C33 is the Rapid React Technology which allows the silage to be fed 7-10 days after ensiling. Silage nutritional quality can also benefit from a faster acid preservation and increased digestibility by using products such as Pioneer Brand 11CFT.

Silage provides the backbone of most dairy rations. Preventing silage problems is important both from a nutritional and economical perspective. Adhering to the management basics for crop management, maturity, dry matter, chop length, compaction, feed-out and ration balancing will help maximise the benefits of fermented feeds.